European

Proportion

26%

The company adheres to customer demand-oriented, and takes "efficient, lightweight, reliable, and easy-to-use" as the design concept to create products with industry-leading technical level and cost advantages to maximize the value of our users.

Proportion

26%

Proportion

31%

Proportion

22%

Proportion

10%

Proportion

8%

· Top engineers in the industry

The R&D member are all graduated from China's 985 and 211 prestigious schools, and have work experience in the world's top 500 companies Emerson and Huawei, also have worked in the power supply industry for more than 10 years.

· Rich technical accumulation

After more than 10 years of growth, our R&D team has grown to nearly 50 people. During the growth, we have accumulated a wealth of industry technical reserves. In solar energy and power technology, we have applied for a number of hardware and software patent copyrights.

· Comprehensive technical support

Our company has different product lines. Each product line is equipped with professional senior R&D engineers and pre-sales/after-sales engineers, who are responsible for new product development and optimization and upgrading of existing products, as well as cooperating with sales staff to solve customers' technical problems in an all-round way.

· professional purchasing Team

A professional purchasing Team has built a huge and complex supply chain system for the company, which makes the company's rapid development more secure.

· Strictly control material quality

Each supplier is strictly selected to ensure the reliable quality of our products from the source.

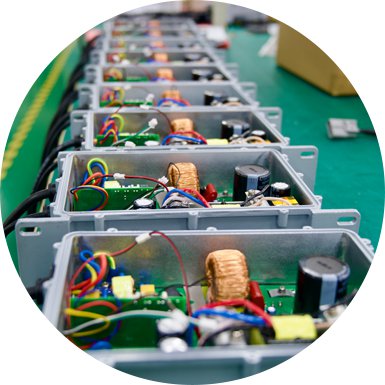

· Efficient production management

The production management of the workshop are all experienced managers from large factories to ensure efficient and safe production operations while ensuring a very high yield rate. In addition, production technology training is provided for workshop employees from time to time.

· Strong production capacity

Our company covers an area of more than 5,000M² with over 100 employees. We have an experienced production team and a comprehensive production system, which can guarantee the production time and quality of the products. We are recognized by new and old customers for our technical expertise and enduring quality.

· Professional & focus

We now have an excellent sales team of more than 20 people, located in different cities. They have good communication skills and a high degree of professionalism for products. All sales personnel are focused on the power supply industry. This excellent team helps the company continue to Growth, but also to provide customers with the most professional services.

· Attentive service & quick response

Our sales team will carry out ability training from time to time, so that they have a high professional quality, will actively reply to customers and seriously help customers solve any product and industry-related problems.

· Strict & serious

Our QC checks every process to make sure all products meet production standards before packing. 100% inspection of the production line. If the received production material is acceptable, the QC inspector will place the PASSED label on the item. Products from production to delivery through layers of quality inspection, to ensure that all products are qualified..

We have passed quality management ISO 9001:2015. In order to ensure that customers get high-quality chargers, every step of the production process is very strict. And all staff entering the workshop and warehouse must wear anti-lithium electrician shoes to ensure the electrostatic environment and hygiene of the workshop.

1. Our semiconductor devices only use high-quality components from internationally renowned brands such as IR.ST.ON, to ensure that no low-quality components enter our warehouse.

2. We have formulated detailed inspection specifications for incoming materials to ensure the quality of incoming materials.

Set up control points in key production stations, and carry out process and quality control of key processes. Such as electrostatic protection, electric batch torque control, etc. There will also be IPQC inspections during the production process.

1. Each charger will undergo a high voltage test to ensure the safety of users.

2. Use an intelligent burn-in system to perform burn-in tests at full load for at least four hours. The system automatically ages the charger after the computer is set up, and records each aging information. Make sure the components of each battery charger are in good condition.

3. Before delivery, we will randomly select chargers for re-testing. Only when there is no problem with this sampling, can this batch of goods be released and sent to customers.

More than 90% of the assembly workers have more than 2 years of experience, so to assemble the battery charger, the efficiency is high and the failure rate is lower.

We provide 24 months long-time warranty, if there are any problems with products, as long as the products meet our warranty terms, we will provide free repair or replacement.

Order finished, our technical support will not finish. If there is any technical problem with products, we have professional engineers always here for you to provide support 24/7.

If there is a defective product in the order or damaged in use, we will provide a new product free of charge and send it to the customer in the next order, subject to the warranty terms.